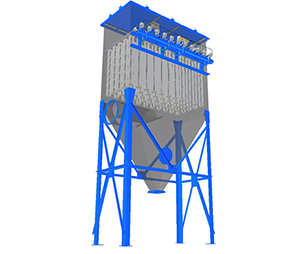

For applications requiring 211 to 1,960 ft2 of cloth area per unit with 20″, 40″, 54″ long filters.

Schust™ LIBERATOR Pleated Element Baghouse provide an industry leading design. To ensure consistent performance we have tuned our pleated collectors around OEM filter characteristics. Can velocities, interstitial velocities, and periphery face velocities have been calculated for each unit. We then configured our collector design with these critical operating factors.

A Pleated Element Baghouse can provide a better alternative to applications suited for a cartridge type collector. Providing a powerful amount of collection in a small footprint, the LIBERATOR pleated element collectors embrace the latest technology advancements.

Features

- Compact advanced pleated design provides more filter area per square foot of collector floor space than traditional cartridge collectors.

- Low profile design suitable for indoor installation. Long duct runs and insulation requirements are often eliminated reducing both initial install costs and daily energy consumption.

- Provides increased filtering capacity for high efficiency application flexibility.

- Economical solution to meet ever increasing regulatory requirements.

- Welded 10 gauge carbon steel construction.

- Operating temperatures to 200°F.

- Filters are changed from the clean side of the collector housing. Operators are not in direct contact with toxic or valuable collected product. Fugitive emissions associated with dirty side change-outs (typical cartridge collector) are eliminated.

- Low compressed air requirements save energy costs.

Comes Complete With

- Spun Bond Polyester filters using EPA/ETV verified media.

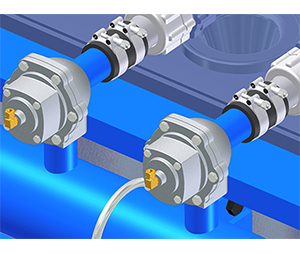

- Double diaphragm pulse valves and compressed air manifold system with NEMA 4 solenoid pilot valve enclosures.

- Programmable solid-state timer controls in a NEMA 4 enclosure. Pre-wired and set-up for continuous cleaning.

- Primed and painted with industrial grade enamel.

- Flanged inlet with safety mesh.