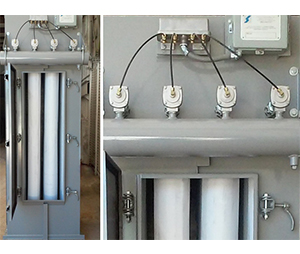

For applications requiring 17 to 432 ft2 of cloth area per unit with 3′, 4′, 6′, or 8′ long filter bags.

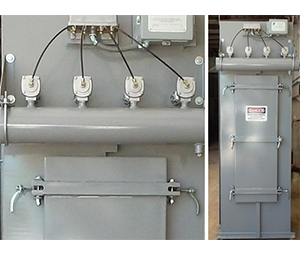

Schust™ LIBERATOR PVB Bottom Access Baghouse models ensure safe filter maintenance from silo-top elevation.

PVB bin vents incorporate a hinged access door with easy-grip zinc-plated handles allowing tool-less entry.

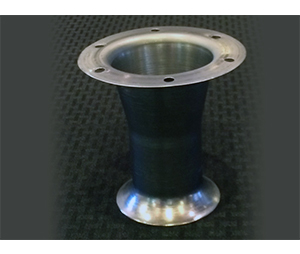

Our OEM venturi design maximizes cleaning potential ensuring pulse efficiency.

Emergency filter change-outs performed quickly regardless of the weather, making the Bottom Access Baghouse bin vent suitable for critical operations requiring minimal down time.

Additional Extended Features

- Units install directly on bins and silos via the supplied flanged inlet. Ductwork is eliminated and installation expenses reduced.

- The PVB series offers 17 to 432 ft2 of cloth area per unit with 3′, 4′, 6′, or 8′ long filter bags.

- Economical solution to meet ever increasing regulatory requirements.

- Welded 12 gauge carbon steel construction.

- Operating temperatures to 275 °F.

- Tuned pulse jet cleaning system with low compressed air requirements to save on energy costs.

- Hinged Access door.

Comes Complete With

- Self-supported 100% Polyester felt filters.

- Rugged 12 wire filter support cages.

- Programmable solid-state timer controls in a NEMA 4 enclosure. Prewired and programmed for continuous cleaning.

- Wire mesh internal bottom grid.

- Primed and painted with industrial grade enamel.

Operating Requirements:

- 115 VAC, 60 Hz. single phase current required for sequence timer.

- 90 to 100 PSIG clean, dry, uncontaminated compressed air supply.